Offshore services

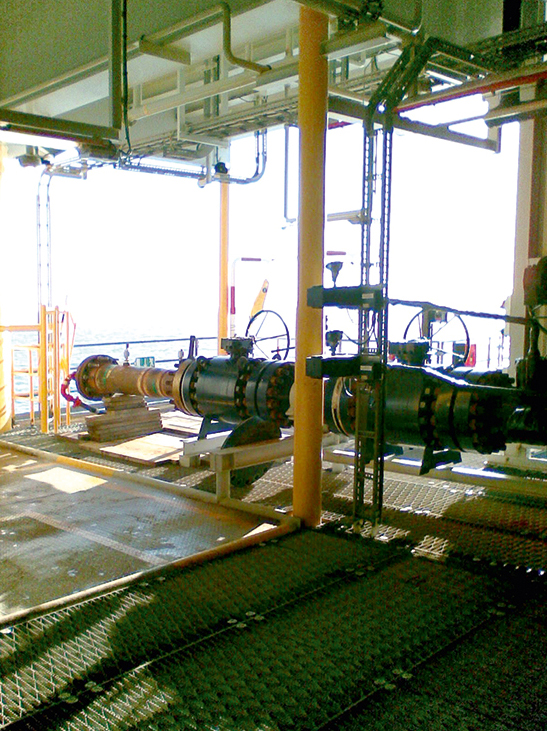

Veenstra Industrial Maintenance engineers specialized in modification, inspection, and maintenance of all kind of valves and pumps on offshore platforms.Contract handling through every stage is geared to meet the fast response times required in the oil and gas industries, with proven success in the maintenance of valves and pumps. Leaking valves lead to a variety of problems including increased maintenance repair costs, and even worse overall inefficient plant operations. Replacing valves is expensive which is why it is important to entrust your valves to a company with expertise, comprehensive facilities and proven track record in maintenance throughout the World onshore and offshore.

Valverepairshop.com

We have a dedicated website about our valve maintenance and repair services both on- and offshore. Please visit our Valverepairshop.com website for more information.

Preventing and solving problems

Veenstra Group maintain, repair and recondition almost any size type and make of valve. Veenstra offshore is also specialized in flush and lubrication of valves. Repairing leaking valves is a laborious and costly operation involving extended downtime production losses. A smooth operation depends on wel greased valves.Plant managers don’t always remember to schedule the valves in a system for regular lubrication. The movement in a valve may only involve opening and closing, but that doesn’t mean valves don’t require the same lubrication as more complex, multipart components.

When even two surfaces must slide over one another, as they do in even the simplest valve, lubrication makes parts last longer and function more efficiently. Veenstra offshore will help you to reduce downtime on your offshore platform by regular lubrication. When a regular lubrication schedule is adhered to, maintenance takes less time, the number of emergencies decreases and the piping system last longer. Most importantly however Veenstra does the job in a safe manner!

We have employees that have all the required certificates for working offshore as well as the educational courses on safety that have been recognized as the standards in this industry. Moreover they got the experience to solve every problem with great precision and speed.